When sourcing dovetail drawers, it’s critical to work with a reliable manufacturing partner so you...

The Dovetail Drawers Difference: What, How, and Why?

Table of Contents

1. Introduction

4. Pluses and Minuses of Dovetail Drawers

5. Conclusion

Introduction

Dovetail drawer is a term that refers to a specific drawer design. A dovetail drawer compartment is made with pins and tails construction that resembles a dove’s tail, hence the name. Drawers featuring dovetail joints are aesthetically, and often structurally, superior to drawers that are constructed with rabbet joints and reinforced with staples or glue to fasten the front, three interior sides, and bottom to one another.

A dovetail joint is highly durable and secures the sides and bottom of the drawer with the front of the drawer in a design that resembles pieces from a jigsaw puzzle. Using trapezoid-shaped dovetail joints to fasten drawer parts makes a strong statement that the manufacturer and the customer alike value quality and longevity concerning furniture and cabinets used in commercial and residential environments alike.

The pins and tails are joined perpendicularly on the drawer’s outside corners and have a distinct, decorative appearance that many people find appealing. This type of joint was used extensively by the Egyptians and Chinese. It pre-dates written history and, more than two decades into the 21st century, it remains a desirable option for quality furniture and cabinets.

Dovetail joints are ideal for drawers, as well as for pull-out shelves. That is because dovetail joints, which are comprised of a wedge-shaped pin and a tail that interlock, have a high tensile strength that allows them to withstand high degrees of stretching or pulling (stress, defined as the measure of external forces acting on the cross-sectional areas of the joints) before they break. In contrast, many drawers are assembled with rabbet joints that do not stand the test of time because the recess or groove used to fasten the joint is relatively weak compared to a dovetail joint.

Drawer Components

Dovetail drawers are of higher quality than drawers joined with staples, glue, or other fastening methods and materials. Nevertheless, they have the same components as their less well-made counterparts. Those components include the front (face), slides, and box.

The Drawer Front is the visible part of the drawer you see when the drawer is closed. The front attaches to the front of a Drawer Box. The box can be a different material or color than the front.

The Drawer Slides are attached to the bottom or sides of the drawer and fit into rails to allow the drawer to move smoothly into the space designed for it in the cabinet, dresser, desk, or other type of furniture. Under-mount slides, including “soft-close” technology, can feature hydraulic dampening that helps the drawer slide in smoothly and quietly with a high degree of consistency.

The Drawer Box is the part of the drawer that stores the items one chooses to put in the drawer. The drawer box’s back, front, and side panels attach to one another using various types of connections, including a dovetail joint.

Types of Dovetail Joints

There are three kinds of dovetail joints: Locking (Through dovetail), English (Half-Blind dovetail and the type shown in the photo above), and French (Sliding dovetail). A Locking Joint is considered the most traditional dovetail joint. It features wedge-shaped cuts at the end of a wooden frame. The strength of a dovetail joint is exemplified by the fact that when a drawer breaks, it rarely does so at one of the joints.

With the average drawer opened thousands or tens of thousands of times during its operating life, it is critical to have a drawer made of material that can “take a beating” especially in apartment buildings or hotels where users may treat drawers harshly because they do not own the furniture or cabinets containing the drawers.

English Dovetail, CCF's typical type of joint, has the dovetail pins visible on the sides but not the front or back. This allows for more straightforward production and consistency than the Through dovetail.

While English Dovetails have numerous “tails” that create exceptionally strong corners, French Dovetails are single-channel cuts in one board, which fits into another board that must be shaped to fit that channel.

Some people consider a Sliding Dovetail joint to be a fourth variety, but it is just another way to describe a French Dovetail because all dovetail joints, by definition, slide into one another.

Pluses and Minuses of Dovetail Drawers

The benefits of dovetail drawers include strength and durability due to how tightly the tongue (tail) cuts into the groove (pin) to create sturdy drawers and cabinets; the ability to showcase beautiful artistry and technique; and the option to disassemble and re-assemble drawers or cabinetry as desired to accommodate renovations or other situations.

Drawbacks include difficulty in marking and cutting, the unforgiving nature of pins and tails that are off by as little as 1/25” (1mm) due to cutting errors or other shortcomings.

Nevertheless, dovetail joints are the best option for drawers that homeowners, or owners of properties including apartment buildings, hotels, schools, and hospitals want to last a long time. Making these joints takes an exceptional amount of skill and dedication to quality. In that vein, we do much of our finishing by hand to ensure the quality we promise our customers.

Conclusion

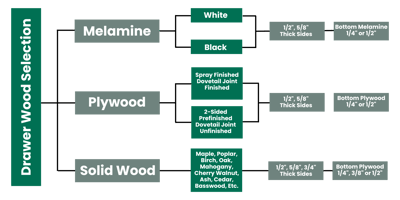

Dovetail joints can be made using almost any kind of wood, including ash, birch, beech, cedar, cherry, mahogany, maple, poplar, walnut, as well as plywood and melamine. Importantly, they all benefit from dovetail joints.

Regardless of your choice of wood, you can’t go wrong with using dovetail joints in furniture and cabinets in residential and commercial settings alike. Apart from our experience and knowledge, along with our commitment to the industry, makes us a valuable partner.

That dedication is illustrated by our membership in the Wood Products Manufacturers Association, the Wood Component Manufacturers Association, the Cabinet Makers Association, and the Architectural Woodwork Institute. These affiliations allow us to stay informed about industry trends, public policy, and more to help us serve our customers in ways that add value to their businesses.

It also gives us the ability to collaborate closely with customers, suppliers, and strategic partners alike to make certain that the quality of our lumber, finished products, and customer service are all the best that they can be.

For expert assistance with selecting the best materials and joining techniques for your application…