At CCF, the quality of our dovetail joints is at the heart of everything we do. That’s why we...

A Solid Resource for Drawer Solutions Designed to Make Your Life Easier

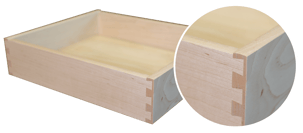

If you are a cabinetmaker, furniture manufacturer, or woodworker who produces drawer boxes, dovetail drawers, or similar products (or if you are an owner, purchaser, or estimator) you know how difficult it can be to economically produce quality cabinetry in a large volume while meeting tight production schedules. Such products include new dovetail drawers; custom drawer replacements; vanity drawers; kitchen, bedroom, and closet drawers; wooden, plywood, and melamine drawers; and dowel and bore drawers.

At CCF, we use our nearly 30 years of being in the drawer manufacturing business to ask the right questions so we can help people like you choose the best materials for the environment where the drawers will be used. For instance, if you are building a custom library in an upscale home, a solid wood drawer box made from attractive and robust hardwood is likely going to be the best material choice.

At CCF, we use our nearly 30 years of being in the drawer manufacturing business to ask the right questions so we can help people like you choose the best materials for the environment where the drawers will be used. For instance, if you are building a custom library in an upscale home, a solid wood drawer box made from attractive and robust hardwood is likely going to be the best material choice.

In contrast, if the drawer is going to be used in an office, or school where it will be subjected to repeated opening and closing, a Baltic Birch plywood or similar material is often best because of its durability and affordability. That kind of material is also preferable for apartment complexes and dormitories in which renters and students may treat the drawers with less care than the owner of a piece of furniture would.

In a healthcare setting, such as a hospital, doctor’s office, or outpatient clinic, plywood or melamine drawers treated with a finish containing antimicrobial additives can be attractive, functional, and economical.

Forming a Reliable Supply Chain

With supply chain disruptions having become a common occurrence over the past several years, we have adapted to this reality by being flexible in our use of material suppliers domestically and abroad to help maintain the promised lead times for our customers. These relationships allow us to structure our production schedules so we can provide regular shipments to customers on a just-in-time basis.

With supply chain disruptions having become a common occurrence over the past several years, we have adapted to this reality by being flexible in our use of material suppliers domestically and abroad to help maintain the promised lead times for our customers. These relationships allow us to structure our production schedules so we can provide regular shipments to customers on a just-in-time basis.

By working at customers’ installation paces, we eliminate the need for customers to endure the hassle of storing our drawers before they are ready to install them. In our experience, this ability to fulfill large-volume orders at regular intervals (e.g., weekly, monthly, quarterly) based on when the customer needs them is something that sets us apart from other drawer manufacturers.

Another point of differentiation is that we always have a knowledgeable team member answering the phone, usually on the first ring, so customers can get their questions answered immediately or directed quickly to the right person for a same-day or next-day response.

By seamlessly tailoring our production schedules to those of our customers, we offer a level of customization that most drawer manufacturers do not. What’s more, by having a wide variety of material options and state-of-the-art manufacturing equipment, we are able to build drawers that fit the customer’s designs rather than force customers’ designs to conform to a limited range of drawer options. To put it in “drawer-speak,” we don’t box you in!

CCF in Action

For a clear idea of how we work with customers, a municipality recently had a rush order for a large volume of stain-coated hardwood drawers. By working closely with them to determine their exact needs, we were able to pinpoint that our clear coat allowed the furniture manufacturer to obtain drawers that matched their specification while meeting the customer’s demanding delivery schedule.

For a clear idea of how we work with customers, a municipality recently had a rush order for a large volume of stain-coated hardwood drawers. By working closely with them to determine their exact needs, we were able to pinpoint that our clear coat allowed the furniture manufacturer to obtain drawers that matched their specification while meeting the customer’s demanding delivery schedule.

Without our ability to work closely with the customer to determine end goals—and our rapid ability to ramp up production for large jobs—the delivery would have been late, and the project’s timeline would have been in serious jeopardy. Instead, the project continued on schedule and within budget.

To find out how we can stay true to your designs while meeting your production quantity goals and delivery schedules….